Initially, Don Bur were looking for a way to prevent unauthorised personnel from working on potentially dangerous shop-floor machinery...

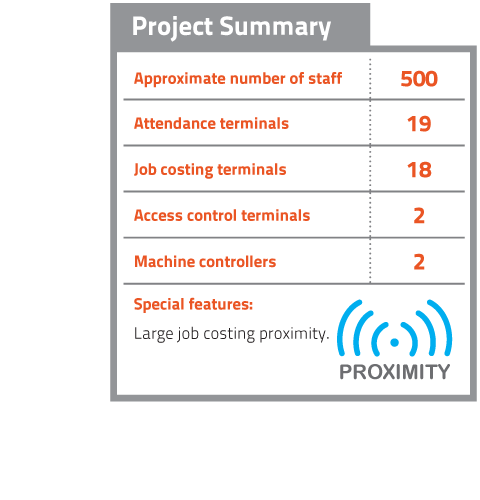

We had searched for several months, without success, for a solution that could be retrofitted to our existing Guillotine and Aluminium Saw equipment when we eventually decided to discuss our requirement with Simon Birchall, MD at timeware® (UK) Ltd. timeware® has previously supplied an extensive attendance, job costing and access control system to the company and we were familiar with their technical expertise and development capabilities.

By coincidence, Simon explained that timeware® were in the early stages of developing a ‘machine controller’ which is an extension of the new asset control module recently released in timeware® 2016. We explained that we required the machine operator to insert their proximity badge into a reader and for certain eligibility checks to be performed before the machine should start. We also explained that removal of the badge from the reader should cause the machine to stop. Following several development meetings over a period of four months, the prototype machine controllers were eventually fitted to the Guillotine and Aluminium Saw by Don Bur’s company electrician and timeware’s® Senior technician Dave Webb.

The eligibility checks performed when the badge is inserted into the reader are:

- Is the employee qualified to use the machine.

- Has the machine been maintained.

The controllers have been in operation now for over three months and we are able to analyses who is using each machine and for how long. It’s also satisfying to know that only qualified staff are able to use this potentially hazardous equipment.

Andy Thurston

Project account manager: Don Bur.