A recent study conducted by Allianz found that disruptions to the supply chain, such as major security breaches, are considered to be the top concern for UK companies. To help combat this, effective security measures must be put in place at every point. One effective security measure is to deploy access control systems at the manufacturing sites that carefully monitor employee movements helping to increase visibility across the whole chain. Simon Birchall, managing director of leading workforce management solutions developer timeware® (UK), discusses how sophisticated access control technology can be used to increase the security of supply chains at the most crucial point.

A recent study conducted by Allianz found that disruptions to the supply chain, such as major security breaches, are considered to be the top concern for UK companies. To help combat this, effective security measures must be put in place at every point. One effective security measure is to deploy access control systems at the manufacturing sites that carefully monitor employee movements helping to increase visibility across the whole chain. Simon Birchall, managing director of leading workforce management solutions developer timeware® (UK), discusses how sophisticated access control technology can be used to increase the security of supply chains at the most crucial point.

According to Allianz, the number of multinational companies has increased from 7,000 50 years ago to 104,000 today. In this globalised era transparency is becoming increasingly difficult as operations expand across continents. This is not just a challenge but a need for globalised control and management of each process throughout the supply chain. One way to monitor operations more closely is to ramp up the security at each individual stage. By limiting authorisation to key personnel and monitoring worker behaviour it is possible to regulate the whole process. As well as the problems that arise through increased globalisation, cyber-crime is becoming more and more commonplace and also poses significant threats to supply chain stability.

These increased risks to supply chains have meant that businesses must put stricter security measures in place at each link. As failure to do so can not only affect revenue but can also have a significant effect on business reputation. Increasing the level of control across the whole supply chain can also improve visibility and control over the overall process.

Even with supply chains that span country borders and even continents, increasing the overall control and visibility of the whole process starts locally. Supply chain protection has to begin with ensuring the necessary security measures are in place at the actual manufacturing site, for example, carefully screening any contents of cargo being shipped.

A recent survey from security firm Pinkerton cited one of the most common security problems associated with supply chains as being poor security at the manufacturing site. This included poor security practices within the shipping and receiving departments and poor access controls. The study also found that the security weaknesses are well known by staff internally 90 per cent of the time.

The need to deploy robust access control measures

To overcome this and to strengthen those security weak spots, businesses must deploy robust access control measures to monitor movements and improve visibility. Because when it comes to supply chains, total control over the manufacturing site has a powerful reinforcing effect across the whole process.

Access control can be described as the selective restriction of access to a place or resource and is crucial when it comes to supply chain security as it can identify any individuals entering the site. Access control can also decide who has the clearance to access both buildings and files and as a result gives organisations greater control over the whole supply chain as individual movements can be traced and monitored. For manufacturing sites, for example, access control can prohibit unauthorised access to shipping, loading docks and cargo areas.

Access control technology becoming more sophisticated

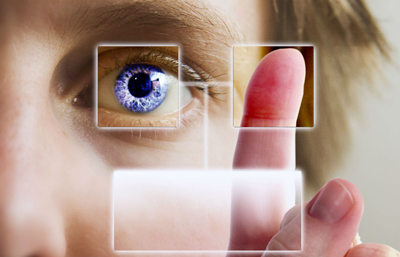

In recent years, access control technology has become more and more sophisticated and modern systems are now using biometrics to optimise security, privacy and convenience across the supply chain.

So why are biometrics so effective? With an ability to prevent issues such as undocumented access, loss of ID cards and ID swapping, biometrics are a formidable alternative to previous access control systems that relied on passwords and physical keys. Nowadays access control and biometric technology has the capabilities to control access points and identify, record and track all employees, contractors, visitors and vendors that may have access to the building. It can also be used to deny access and trigger an alarm when anyone attempts to enter an area without jurisdiction. New technology can even control the times individuals have access to facilities.

The level of sophistication available with biometric access control technology means that authentication can be taken one step further. Biometrics actually have the ability to monitor behaviour and can take into account the way in which the person interacts with the device, for example, the force that they hit a key. This has massive implications for the supply chain as everyone involved in the process, from the manufacturers to the distributors, can be carefully monitored and screened.

Using access control to protect people and property

An example of the latest access management technology available to businesses is timeware’s® access control package which focuses on protecting the two most valuable assets; people and property.

The timeware® software is designed to ensure than when a distributor completes a job or when an individual leaves employment, they will no longer have access to the building. The access control technology can be fitted to any door and biometric readers will ensure only authorised personnel have access through it. Once the system is installed, it is possible to produce reports on staff movement and to track individuals around a site. It’s also possible to give visitors and contractors temporary access to ‘public’ areas with badges that will cease to function after a pre-determined time.

Sophisticated access control technology has the ability to strengthen security at the crucial point in supply chains, such as the manufacturing sites. Reinforcing the security at this critical point can help to increase visibility across the whole supply chain. More and more businesses are installing a variety of access control technologies to increase control at the point where it is needed the most.